Because it is required to comply with GAAP to get a manufacturer’s financial statements. Utilities, such as natural gas, electricity, and water, are overhead costs that vary depending on the volume of commodities produced. Depending on market demand for the goods, this could increase or decrease. For example, the wood pulp used in the paper industry is not considered an indirect material. However, the lubricant necessary to keep the machinery working smoothly is an indirect cost imposed during the papermaking process. For instance, even if your company decides to reduce production for this quarter, you must continue to pay the same amount for renting office or manufacturing space.

Step 4: Apply Overhead to Jobs or Products

If you only take direct costs into account and do not factor in overhead, you’re more likely to underprice your products and decrease your profit margin overall. These are costs that are incurred for materials that are used in manufacturing but are not assigned to a specific product. Those costs are almost exclusively related to consumables, such as lubricants for machinery, light bulbs and other janitorial supplies. These costs are spread over the entire inventory since it is too difficult to track the use of trial balance these indirect materials. When you do this calculation and find that the manufacturing overhead rate is low, that means you’re running your business efficiently. The ripple effects of overhead calculation accuracy extend deeply into profitability analysis.

Different Types of Overhead Costs

Furthermore, investing in employee development will create an engaged workforce that is more efficient and productive. Additionally, it is an essential guide for setting benchmark targets for improvement over time. Analyzing these percentages can also help identify potential areas for cost savings, which can further improve operational efficiency and profitability. Keeping this metric high ensures smooth operations, timely deliveries, and satisfied customers. Prioritizing real-time tracking and automation can enhance decision-making and ensure smoother how to find manufacturing overhead rate operations.

How to Calculate and Budget Manufacturing Overhead

- Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week.

- Additionally, these specialized tools often provide robust audit trails and documentation of allocation methodologies, which supports compliance requirements and provides transparency in cost calculations.

- Heavy equipment manufacturers with long production cycles require overhead allocation methods that account for extended timeframes.

- Manufacturing overhead cost per unit is the total indirect costs allocated to produce one unit of product.

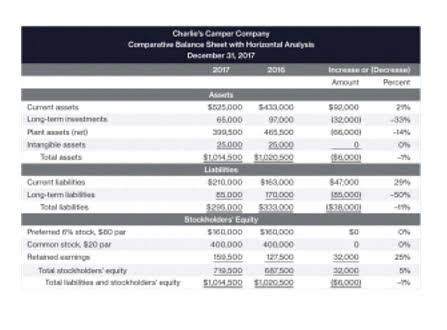

This $4 per DLH rate would then be used to apply overhead to production in the accounting period. The difference between actual and applied overhead is later assessed to determine over- or under-application of overhead. This calculates the percentage of indirect costs relative to direct costs. You’ll master the key formulas, learn how to allocate costs properly across departments, see real-world examples, and discover best practices to control overhead expenses. Choosing an appropriate allocation base emphasizes a causal relationship.Create like a pro — no skills required SnapNinja AI Belgium.

These are the hours spent by workers who are directly contributing to the production process. Manufacturing overhead is an essential part of running a manufacturing unit, and utilizing robust manufacturing accounting software can significantly streamline the tracking and management of these costs. Tracking these http://www.surancardak.com/2022/09/14/what-is-the-equity-multiplier/ costs and sticking to a proper budget can help you to determine just how efficiently your business is performing and help you reduce overhead costs in the future. Now that you know how to calculate manufacturing overhead, you can better budget for your indirect costs.

Add Overhead Costs

For businesses with varied production activities, ABC assigns costs more precisely. You track each activity (e.g., machine setup, quality testing), and apply overhead based on how much of each activity a product consumes. Let’s say your cost driver is direct labor hours, and your team logged 400 hours this month.